Translate:

Different types of material used to make ladders

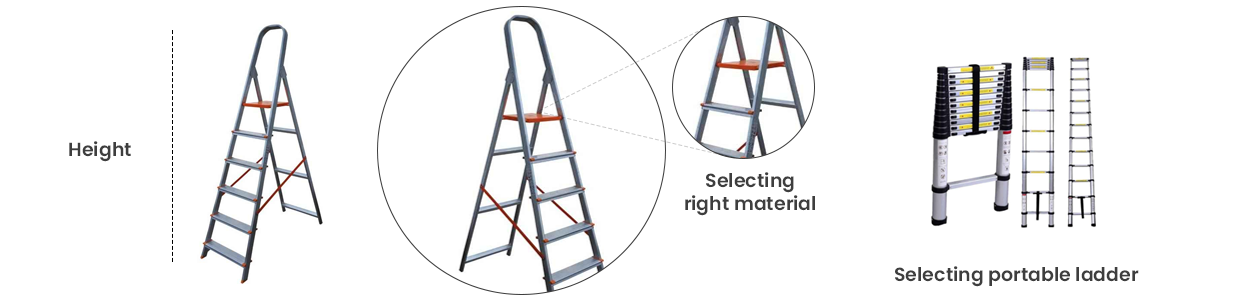

Ladders come in different shapes, sizes and are also made of different materials. Choosing the wrong material may result in a waste of your money and increase the risk of getting injured. Your choice of material may not just affect the price but also the overall product longevity.

Therefore, it is important to know the types and benefits of each material before selecting a suitable ladder. For your convenience, we have included some of the distinctive qualities of each material below. Check them out.

Aluminium ladder:

These ladders have several advantages: they are lightweight and durable, and they can typically be stored outdoors without worrying about the ladder getting damaged. In addition, aluminium ladders, also called metal ladders, are far lighter than their wooden or fiberglass counterparts, making them easier and safer to handle for a single person. These defining characteristics make them ideal for those fast DIY adjustments.

Furthermore, ladders made of aluminium are highly adaptable in terms of structure, with some alloys providing structural steel-like strength. Unlike iron ladders that are prone to rust, the hallmark resilience of aluminium ladders makes them oxidation resistant, allowing them to avoid the worst effects of rust and bad weather.

However, because aluminium is highly conductive, it is susceptible to electric shocks and rapid temperature changes. Therefore caution is advised in these situations; if possible, another ladder should be used instead.

Top Sellers

Wooden ladder:

Wood is one of the most commonly used materials for ladders since it is inexpensive and readily available, making it a popular choice among homeowners and small company owners. However, the longevity of wooden ladders varies depending on the type of wood used.

Hardwoods including hickory, alder, beech, oak, and mahogany are the most common wood used to make ladders. These sorts of wooden ladders are robust enough and offer similar strength as steel ladders. Softwoods such as pine, spruce, and cedar are also used to make other ladders. However, it would be best to avoid these types of ladders because they are the least adaptable.

Although a wooden ladder will not rust, it will deteriorate if left out in the open, especially in wet weather, making it potentially unsafe. Therefore, you must keep these ladders indoors to avoid this issue.

Steel ladder:

These ladders are suited for heavy-duty applications and are a warehouse essential. Warehouse employees have no qualms about their safety when rolling around these ladders because they are heavier and more durable than aluminium and fiberglass. Steel ladders are rigid and can withstand hundreds of pounds, which is why they are a viable option for industrial use. However, these kinds of ladders are not suitable for DIY tasks.

Steel is an iron alloy and is an excellent electrical conductor; hence this type of ladder is chosen in warehouses and other enclosed locations where high-voltage electrical installations are not present. Rusting was a significant issue with steel in the past, but the problem no longer exists since the development of stainless steel alloys. Furthermore, because these ladders are mounted on rolling wheels with solid rails, their larger weight is no longer a concern in warehouses where they can be easily moved around. But ladders made from stainless steel alloys are highly expensive and heavier, making it difficult to transport them from one place to another.

Plastic ladder:

These ladders are the most cost-effective option for a few simple tasks. They are made of polyester resin reinforced with glass fibers, also called fiberglass. This is one of the newest materials in ladder construction and offers specific advantages over other materials. For example, fiberglass ladders are the safest ladders to use since they resist electricity, providing extra support even when working on wet surfaces.

Physically, plastic ladders or fiberglass ladders are incredibly robust, even stronger than aluminium in some circumstances. Still, they lack the high resistance to the weather that makes wood ladders so valuable. However, they are heat and electricity resistant, and unlike wooden ladders, they won't decay.

Plastic ladders, on the other hand, have several disadvantages. While its heavy weight makes it more durable and often safer than other ladders, they are difficult to operate by one person; hence, they are more commonly employed in commercial or industrial settings than at home. Furthermore, fiberglass ladders are also more prone to breaking than aluminium ladders, demanding more frequent inspections, and they are highly expensive.

Conclusion:

Selecting the suitable ladder material plays a crucial role in ensuring your safety and the durability of the tool. Additionally, not all materials can resist electricity and therefore must be avoided in wet environments. If you want to buy one of these ladders from a genuine marketplace, we recommend going through Moglix. Here you will find an incredible collection of ladders made of different materials at the best prices.